Full-Service Machine Shop

Aside from our standard product line, Hardware Specialties has a fabrication and machine shop where we perform custom fabrication for contractors daily.

We manufacture all of our standard and custom sneeze guards from our manufacturing facility in Ontario, California. So, if it’s the stainless steel sneeze guards you looking for, we can provide you with a top-quality product at affordable rates. And what’s more, our standard quality sneeze guards are ready to ship anywhere in the U.S.A. or internationally.

Being a manufacturer and a fabrication shop, we can also manufacture custom security gates based on your specifications.

Contact us for more details about your custom products. (909) 975-4853

Polishing Services

Our in-house polishing facility occupies over a quarter of our industrial facility located in Ontario, California. From this location, we are able to service contractors in California, and the U.S..Whether your project requires stainless steel, brass, or carbon tube, round bar or square, rectangular, flat bar, or sheet polishing, we can provide you with service unsurpassed in the industry, fast turn around times (on most polishing projects), and competitive pricing.

Production Cutting

We offer complete in-house, state of the art cutting services. We can provide you with 90 degree and Miter cuts on Round Tube or Bar, and Rectangular, and Square Tubes. If you are working on something as simple as a custom sneeze guard to complex handrail systems, we have the capabilities to complete your production cutting job.

Sheet Rolling

Our rolling capabilities include rolling stainless steel sheet, brass, carbon, or any other type of metal plate and sheet. Rolling steel has a wide variety of applications for manufacturers and contractors of end products for example retail store removable case guards. In addition, utilizing our in-house rolling capabilities allows cost savings, quality control and improved lead-time.

Sheering

Our in-house sheering capabilities provides a cleaner cut over flame cutting. Shearing can be as small as 1″ all the way up to 12′ in length. For contractors who require their carbon (up to 3/8″ thick) or stainless steel (up to 1/4″ thick) sheered, Hardware Specialties can handle your custom fabrication order.

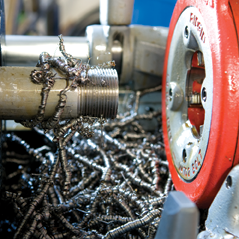

Pipe Threading

Hardware Specialties offers pipe threading for both carbon and stainless steel pipes using the National Pipe Threading (NPT) standards (ANSI/ASME B1.20.1). Our services include 1/8″ to 4″ pipes, up to schedule 40.

Deburring

We offer both OD (outside diameter) and ID (inside diameter) deburring services on round and square steel tubes. It’s always a good idea to have your steel deburred after it has been cut. Deburring provides for safer handling of tubes as well as providing a cleaner product. Deburring is the process of removing the metal shavings after cutting the metal tube. While basic deburring is conducted on all steel tubing cut by Hardware Specialties, it’s recommended that all of your cut tubes be put through the complete deburring process which helps reduce cuts and injuries when handling the metal in the field.